If you have already enquired with us in the past; you may have noticed that some items we quote include a one-off tooling charge. We try to keep costs to a minimum so we can offer you competitive prices; but sometimes these extra charges are unavoidable.

Providing the component drawing doesn’t change, then often these tooling charges are only ever charged once and can last multiple years.

Why is tooling necessary?

Moving Manufacturing Processes

Paying a one-off cost up front for tooling can mean you benefit from better piece prices on your components.

For example, we could move component manufacture offshore to be forged or cast and we would charge a one-off fee to create the tooling and moulds needed for this process. However, the casting process is easily repeatable and allows for quick bulk manufacture so the piece price of the parts would often be significantly cheaper compared to CNC turning or milling.

Increasing the yield

Particularly for punching processes; the tooling charges may be for creating bespoke tooling to punch multiple parts at once from the same sheet of material. This would reduce the cycle time of manufacturing the parts; which would lead to a cheaper piece price.

Bespoke Sizes

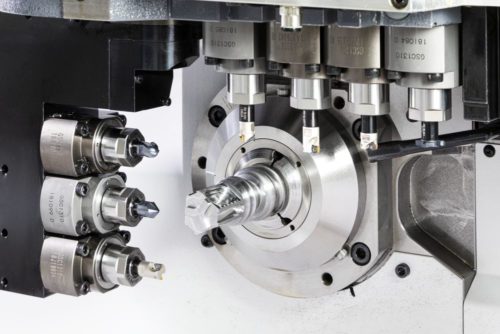

Sometimes the size of the raw material may not fit the machine, and bespoke collets are required in order to accommodate this. Alternatively, if the component has bespoke threads of tight tolerances, then we may need to replace the tooling more often to ensure the high quality expected can be held.