As a manufacturer and supply chain solution provider, we are always under pressure to meet tight lead times and increase the speed of our manufacturing operations. Where it doesn’t impact on the final quality of the part; reducing cycle times can be one of the easiest ways to speed up production; and this also has a cost benefit to all parties involved.

Essentially, if we can manufacture your components more efficiently, not only can we get product to your door quicker, we can also cut our own operational costs which will have a positive impact on your pricing.

Techniques to reduce cycle time

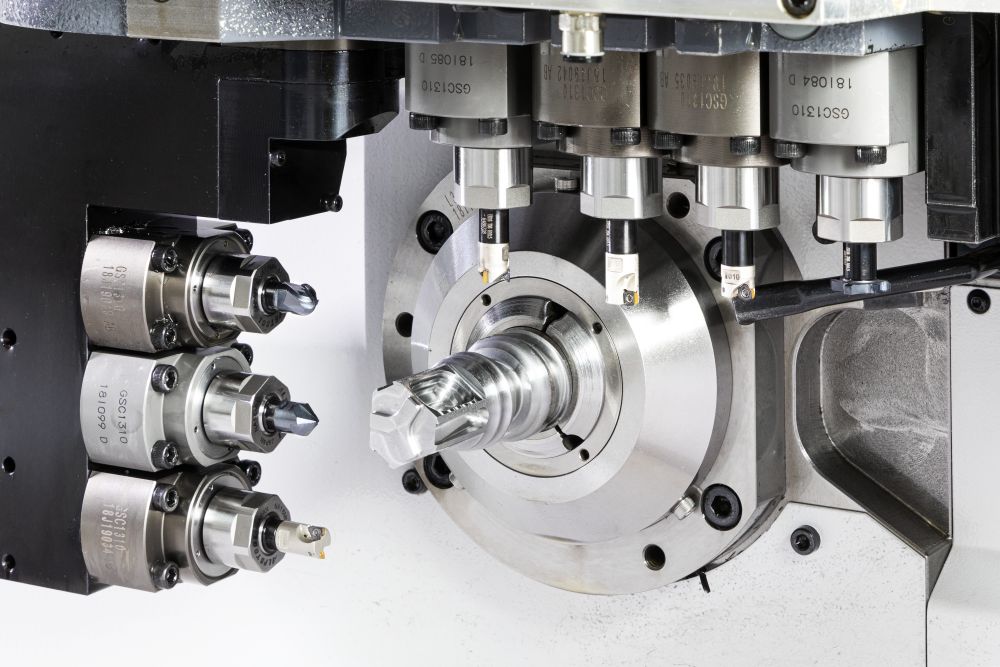

Selecting the most efficient machine for the job

It might seem self-explanatory but different machines, with different tooling setups, material feeds, and cutting techniques etc. all have different speeds of manufacture.

Selecting the correct machine for the job can greatly reduce the cycle time.

Using suitable material

Material hardness has a direct impact on the cutting speed; the harder the material is, the longer it takes to machine.

Where possible, using a softer grade of material can increase the cycle time – find out more about the common materials we use by reading our Material Choices blog post.

Limiting down-time

Replenishing material and tool changes all cause the machine to be stopped and, when the machine is idle, no parts are being made.

Optimising the program to group together the passes each tool makes; and using automatic bar feeders, can let the machine run almost autonomously and improve the overall cycle time.

Benefits of shorter lead times

Improved lead time = improved cash-flow

Quicker lead times not only has a direct impact on you, as you get your stock more quickly; but it impacts all facets of our business when cash can move in and out quickly.

It’s quite simple, the quicker material can be turned into parts and pushed out of the door to customers; the quicker we get paid and can spend that money on securing more material, equipment, or other assets for projects we are working on for you.

Per piece cost reductions

The quicker we can manufacture the part, the less time the machine is actually operational and running.

This means the overall running costs are less so, when shared across all of the components produced, it will decrease the piece price.

Improved customer satisfaction

We always strive to keep our customers happy, and the best way is to provide quality components; on time and in full.

It might not seem like much, but shaving a couple of seconds per piece off the cycle time can greatly impact the overall speed of delivery.