Unless you are familiar with the processes involved; CNC Milling and Turning might seem the same, as the end products would look similar in terms of the finish, and both involve the removal of stock/raw material to form the desired shape. In its most simple terms; this would make it hard to determine which option is “the best” as it depends on what component is being made.

However, there is a difference between the 2 processes; and the best method should be chosen to fit the requirements (shape & size, intricacy, production volume etc.) of the part being made. Choosing the correct method could save on the machining cycle time, and ultimately make the part more economical to produce.

So, what is the difference?

Very simply; the difference between the process involved is based on what is moving; the machine moving tools to cut the material, or the raw material itself moving with the machine staying still.

In Milling, the material remains stationary on a bed, and the cutting tools rotate around the material to cut and form the required shape. This lends it hand to creating complex components such as tooling or intricate mechanical parts, as the tooling can move on multiple axes to cut in multiple directions.

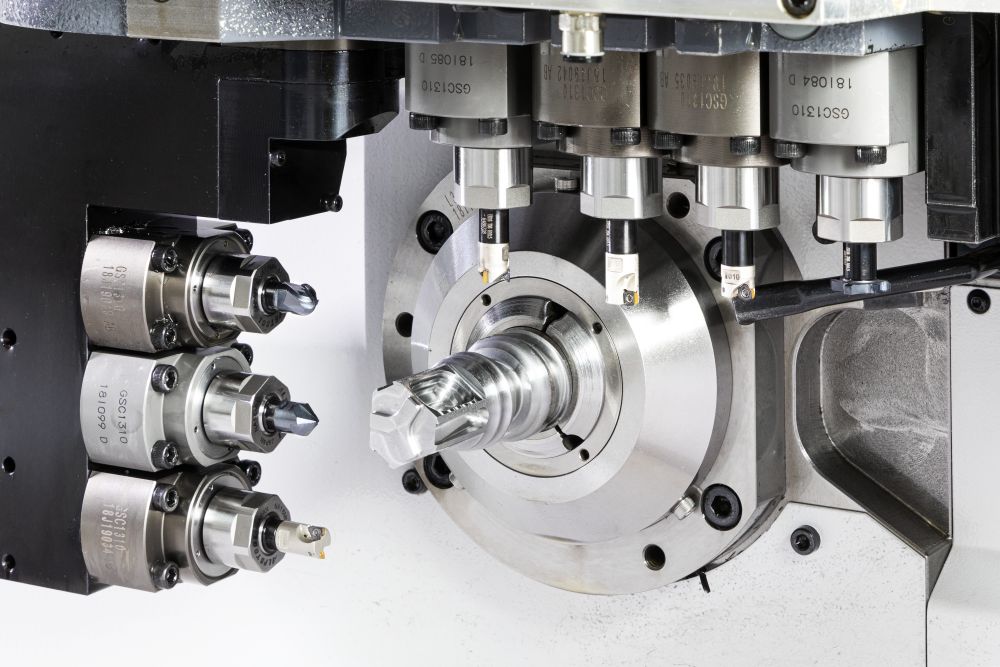

On the other hand, the turning process (as the name suggests) involves the material rotating at speed and moving into stationary cutting tools. This makes turning the more common method to produce cylindrical parts, such as olives, valves, tubing and hollow sections.

|

Milling |

Turning |

|

|

Typical Shapes: |

Flat squares/rectangles or irregular shapes | Conical or Cylindrical Shapes |

| Tooling Options: |

Multi Point/Axis Cutting Tool |

Single Point Cutting Tool |

| Cutting Options: |

Continuous cutting (the tool remains in contact with the material) |

Intermittent cutting – the cutting tools move to and from the material |

| Waste/SWARF: | Produces discontinuous chips |

Produces fragments, discontinuous or continuous ships |

Visit our case study page to see parts we have supplied using these techniques for your specific industry.