Any company or any industry that requires parts made to a high level of precision will utilise CNC Machining.

You may already buy in components that were most likely manufactured on some sort of CNC machine.

What is a CNC Machine?

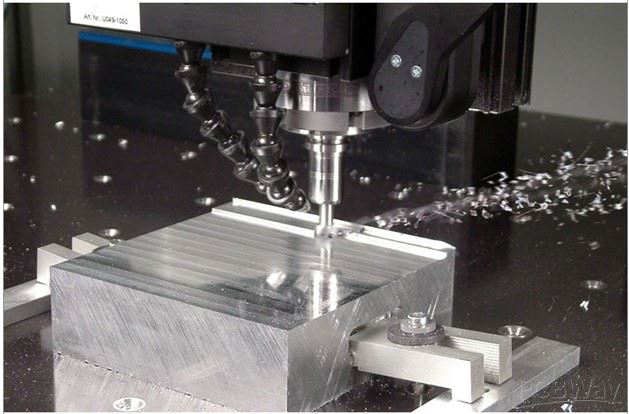

CNC stands for Computer Numerical Control; so a CNC milling or turning machine is controlled and monitored through the use of dedicated computer software. The component are drawn out and programmed into the computer; which is then used to control the movement of the tooling of the machine to cut away the material into the desired shape.

What industries use CNC Machining?

- Boiler and HVAC manufacturers

- Aerospace manufacturers

- Medical equipment

- Automotive & transportation

- Military/Defence

- Catering equipment manufacturers

- Bathroom/Plumbing parts

What are the benefits of CNC Machining?

Compared to more manual methods of machining; there are many benefits to choosing CNC Machining, including:

- Higher level of precision

- as long as the machine is programmed correctly, there is little chance of human error

- the machine itself and tooling used can also work to tighter tolerances so can be made to the exact specification required

- the same program is used to make multiple parts so there is a higher level of consistency across the batch

- Cost Effective

- One trained operator can setup and run multiple machines at once which can save in labour costs.

- The cycle times are also quicker with more advanced machinery so machining and running costs are also less.

- Efficiency

- Dependant on the machine used, multiple tools required for the job can be loaded at once so tool changes can often be completed automatically.

- Some machines also have automatic bar feeders so the material is fed into the machine without the need to wait for human intervention to complete this